Fluid heatsinks

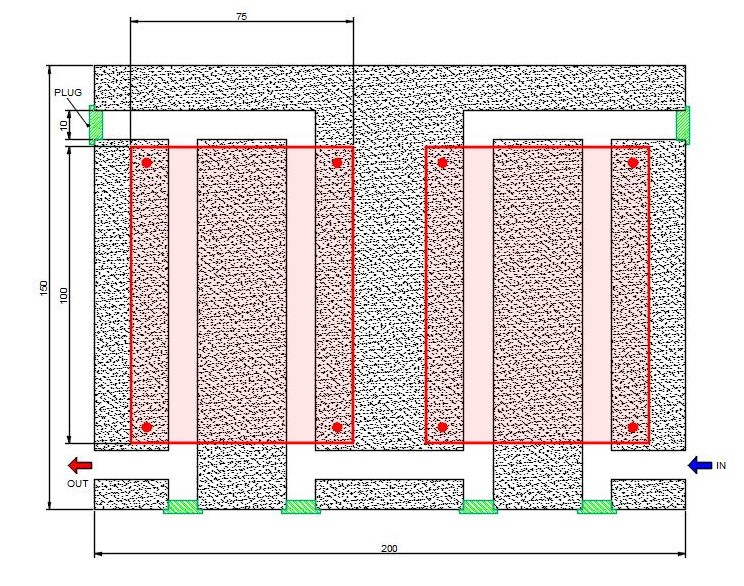

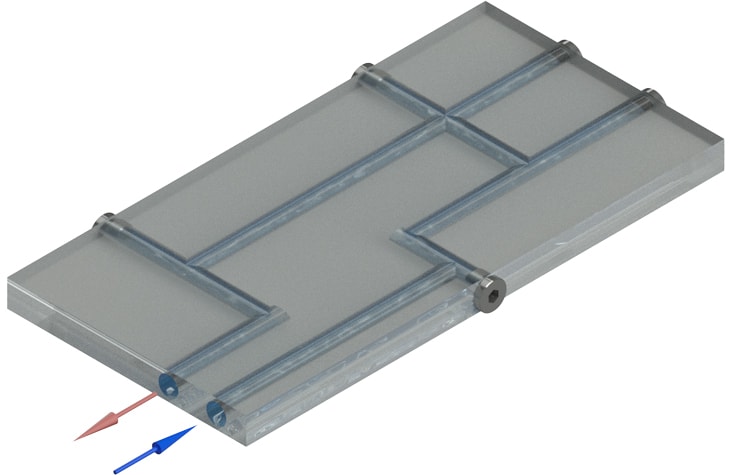

The plates for liquid cooling heatsinks with through-holes are produced through direct extrusion or deep drilling of solid plates

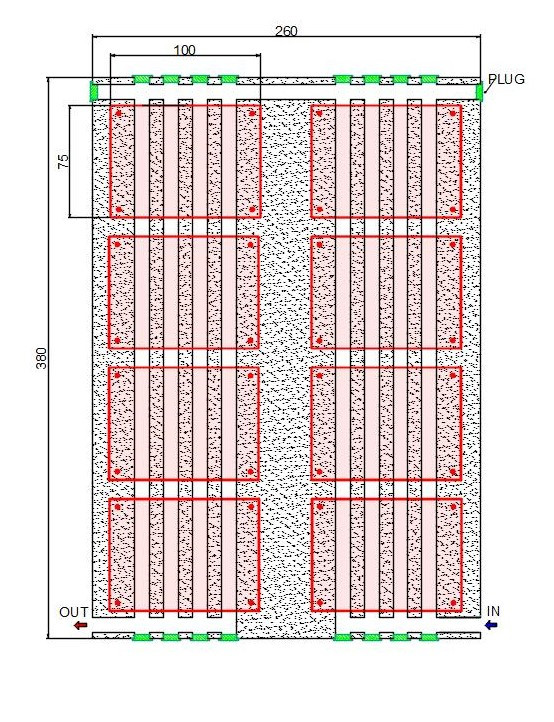

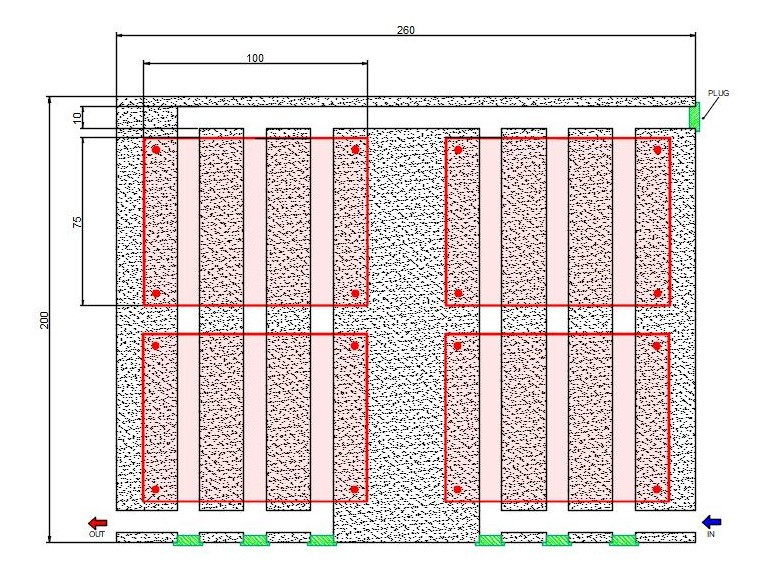

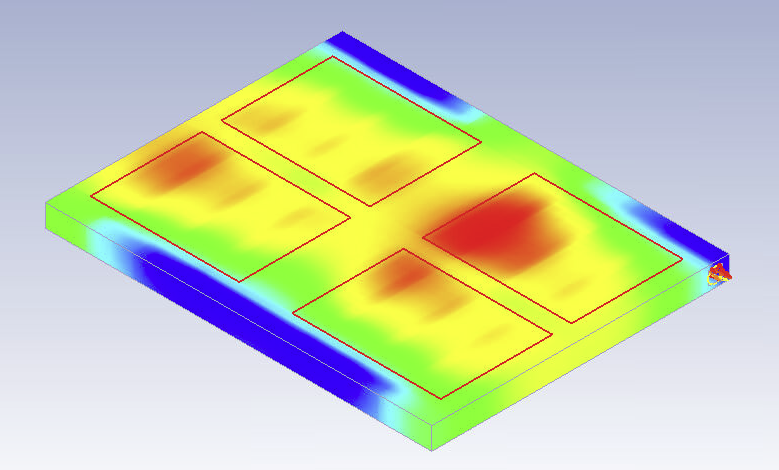

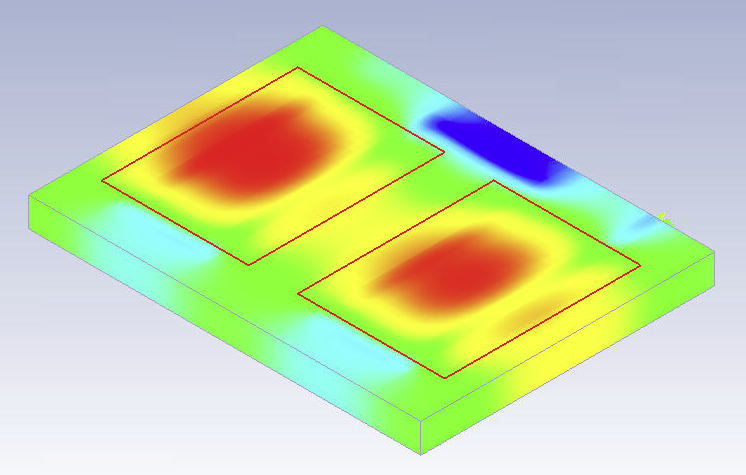

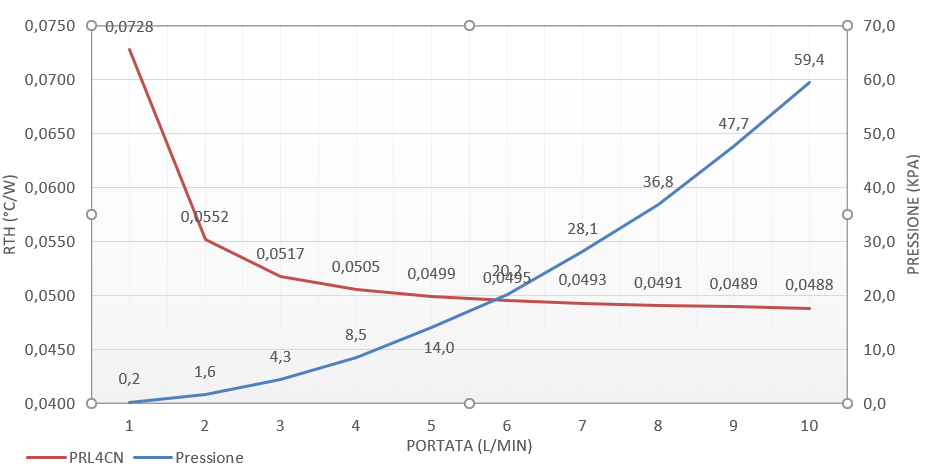

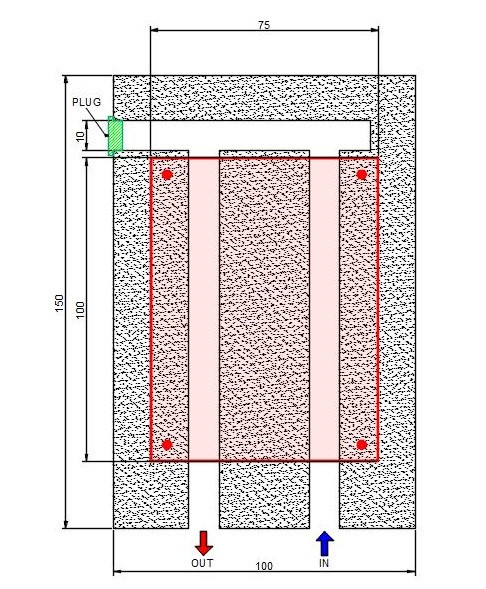

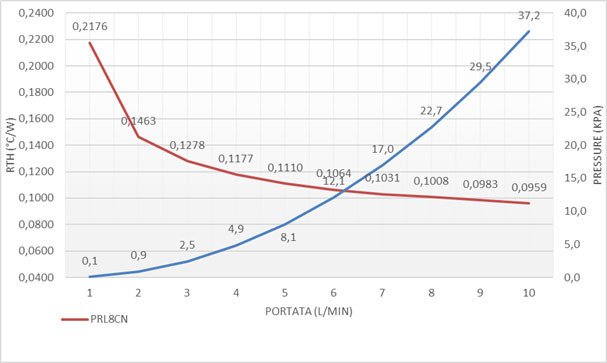

Through-hole liquid coolers are obtained directly by extrusion or by deep drilling of solid plates. The channel circuit, whether extruded or custom-designed, is obtained by sealing the channels themselves, both externally and internally at specific points defined by the customer's design, with the use of sealed plugs positioned to define the circulation of the liquid inside the plate.

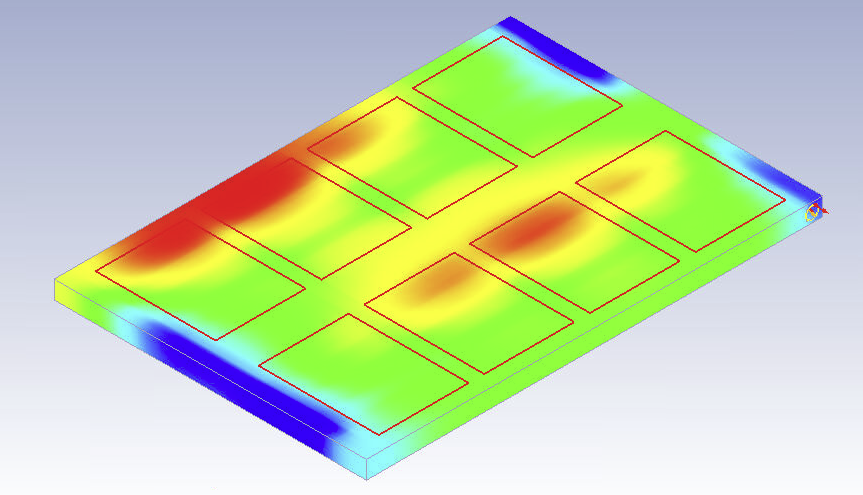

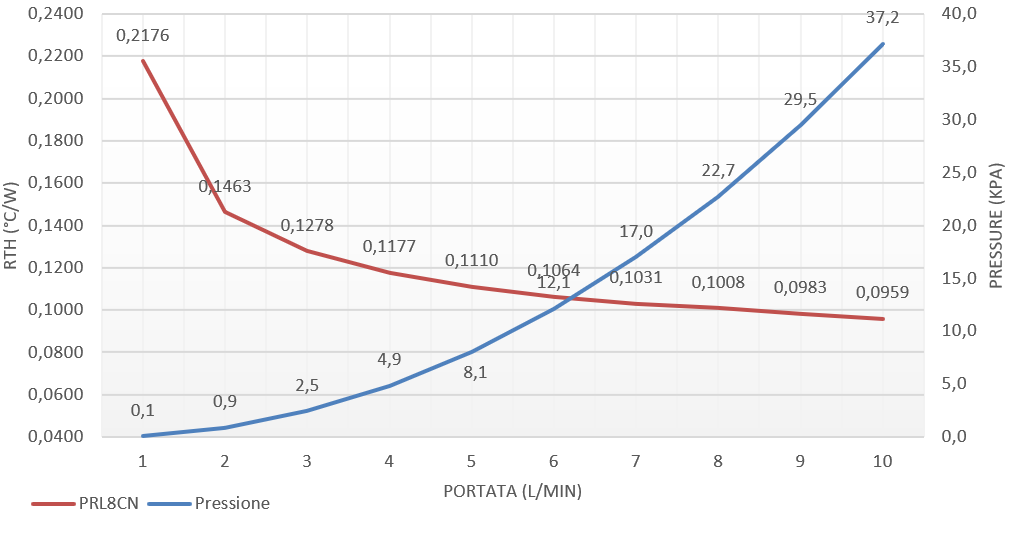

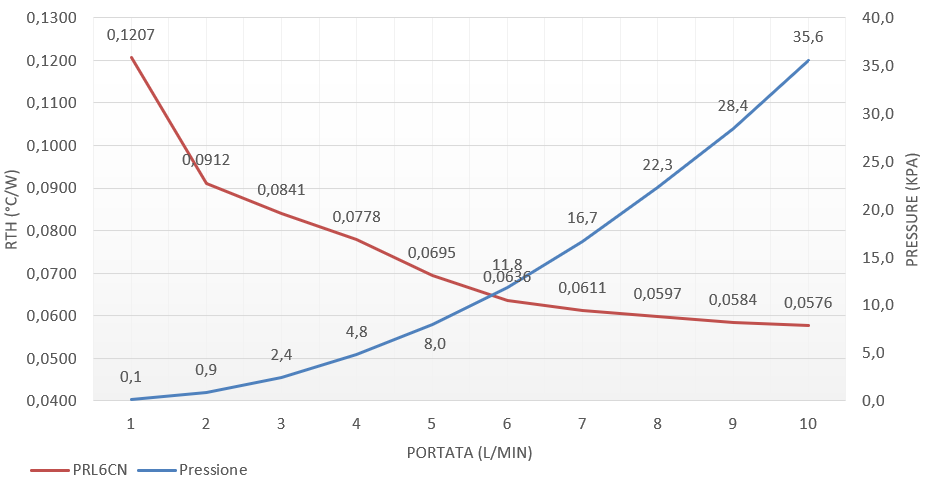

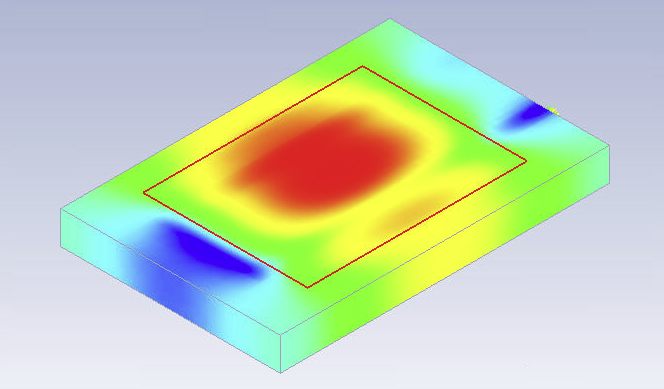

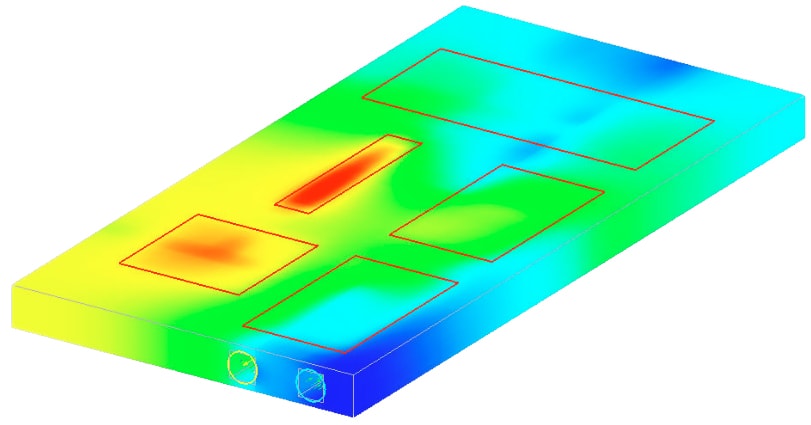

TRE-S can adopt different solutions at the customer's discretion in order to achieve maximum performance in the components it assembles through thermal studies, since water cooling is increasingly becoming the ideal alternative to dissipate the high powers produced by the new generation of IGBT transistors.

Advantages of the liquid cooler:

- The possibility of separating the area where power is generated, which is usually limited, from the dissipation area

- Avoid noise and vibration problems

- Used in dusty environments where forced air is not possible