Prodotti

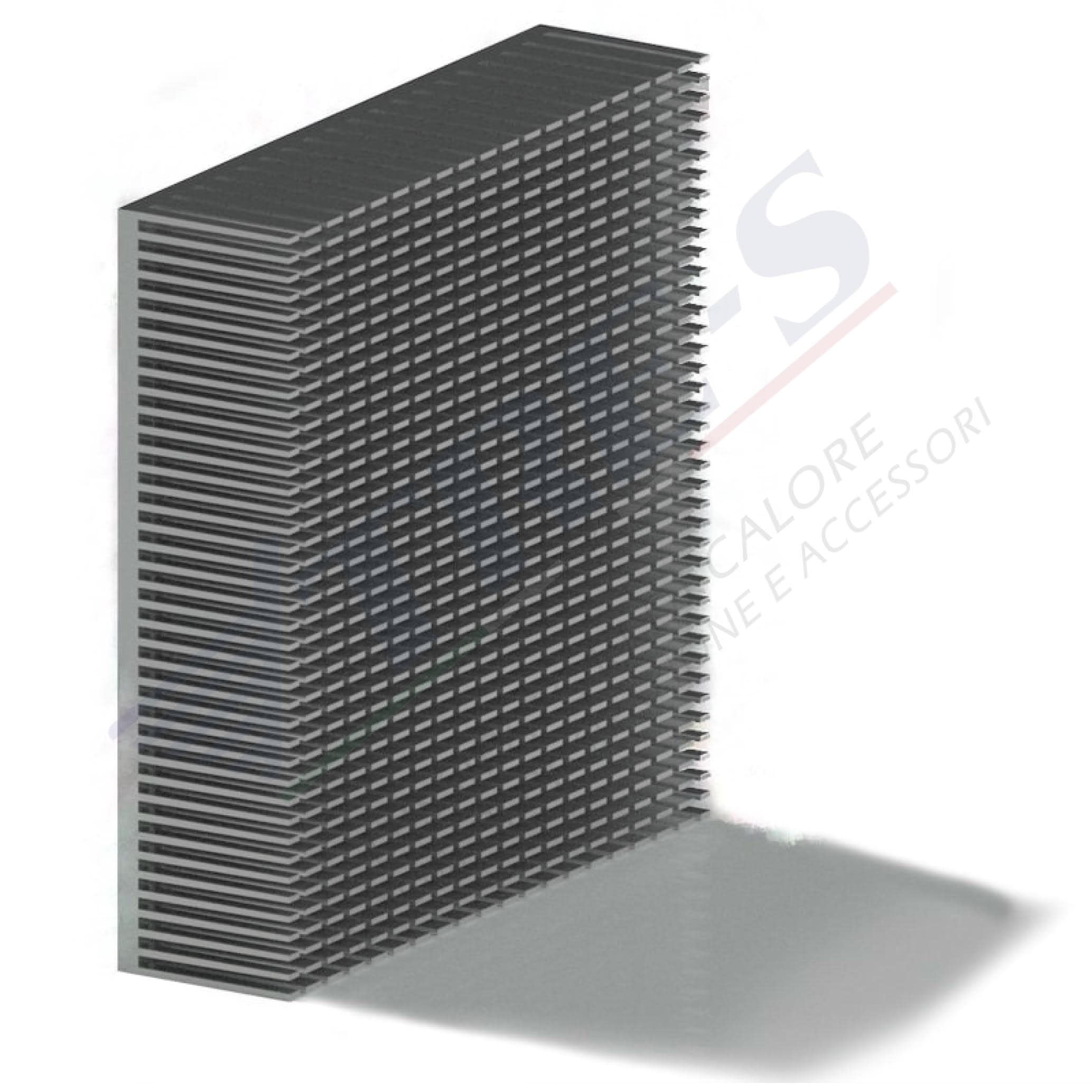

Assembled heatsinks

Heat sinks characterised by materials that can be aluminum and copper, which are made through a molecular chemical fusion between the solid and the fins, in order to make the custom heatsink super performing. Increasing the dissipation surface area by having a narrower fin pitch.

Heatsinks with clip system

Heat sinks fitted with an elastic element to hold the components applied to it. The advantage of this system is that it ensures an effective seal of the components applied by means of a fast-applying clip consisting of a sheet of elastically deformable material which does not require any special processing.