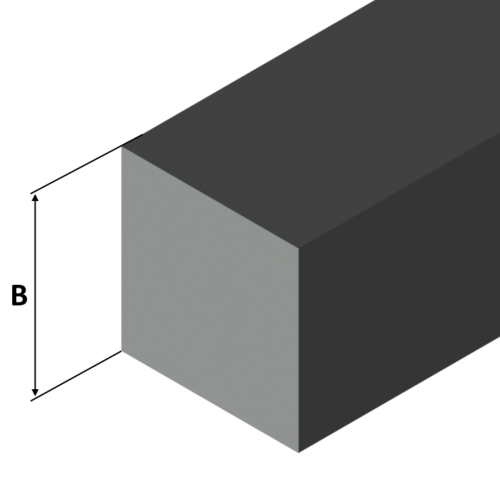

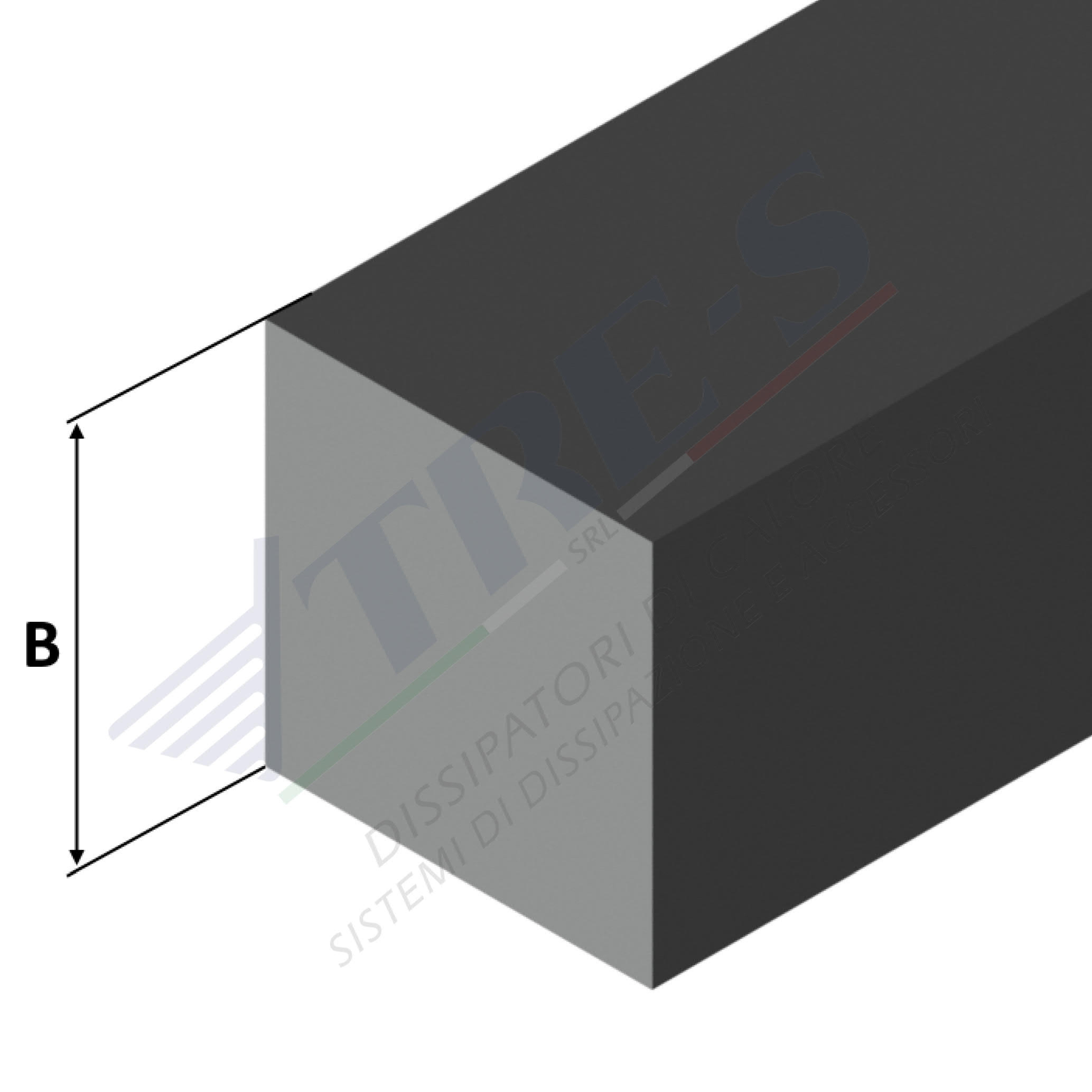

Code: Barra quadra

Standard Profiles

| Lega | BxS Dimensione | Peso al metro |

|---|---|---|

| 6060 | 6 | 0,098 |

| 6060 | 8 | 0,173 |

| 6060 | 10 | 0,27 |

| 6060 | 12 | 0,338 |

| 6082 | 15 | 0,608 |

| 6060 | 15 | 0,608 |

| 6082 | 18 | 0,875 |

| 6082 | 20 | 1,08 |

| 2011 | 20 | 1,08 |

| 6060 | 20 | 1,08 |

| 6082 | 25 | 1,69 |

| 2011 | 25 | 1,69 |

| 6082 | 30 | 2,43 |

| 2011 | 30 | 2,43 |

| 6082 | 35 | 3,307 |

| 2011 | 35 | 3,307 |

| 6082 | 40 | 4,32 |

| 2011 | 40 | 4,32 |

| 6082 | 45 | 5,468 |

| 6082 | 50 | 6,75 |

| 2011 | 50 | 6,75 |

| 6082 | 55 | 8,168 |

| 6082 | 60 | 9,72 |

| 2011 | 60 | 9,72 |

| 6082 | 65 | 11,407 |

| 6082 | 70 | 13,23 |

| 2011 | 70 | 13,23 |

| 6082 | 80 | 17,28 |

| 2011 | 80 | 17,28 |

| 6082 | 90 | 21,9 |

| 2011 | 90 | 21,9 |

| 6082 | 100 | 27 |

| 2011 | 100 | 27 |

| 6082 | 110 | 32,67 |

| 2011 | 110 | 32,67 |

| 6082 | 120 | 38,88 |

| 2011 | 120 | 38,88 |

| 6082 | 130 | 45,63 |

| 6082 | 140 | 52,92 |

| 6082 | 150 | 60,75 |

| 6082 | 160 | 69,12 |

| 6082 | 170 | 77,03 |

| 6082 | 180 | 87,48 |

| 6082 | 200 | 108 |

| Codice | KN MAX | I | F | H |

|---|

| Codice | KN MAX | I | F | H |

|---|

| Codice | KN MAX | I | F | H |

|---|

| Codice | KN MAX | I | F | H |

|---|

| Codice | KN MAX | I | F | H |

|---|

| Codice | KN MAX | I | F | H |

|---|

Length: 0.00 mm

Weight: 0.00 kg/m

Weight A: 0.00 kg/m

Weight B: 0.00 kg/m

Height: 0.00 mm

Within this catalog, heat sinks are organized based on their shape and dimensions expressed in millimeters. Each profile is characterized by the following parameters:

- Weight: expressed in kilograms per meter of profile length (Kg/m).

- Length: indicated in millimeters and used for calculating thermal resistance (L).

- Width: also in millimeters, considered for calculating thermal resistance (°C/W), applicable only to high-efficiency heat sinks.

- Thermal Resistance in Natural Convection: expressed in °C/W with a temperature difference of 70°C (compared to an ambient temperature of 25°C).

- Thermal Resistance in Forced Convection: also expressed in °C/W, with an air velocity of 3 m/s and a temperature difference of 50°C.

The values of thermal resistance have been determined through a thermal simulation program designed to replicate realistic conditions. In particular:

- The heat source is uniformly distributed over approximately 50% of the dissipation surface, with central positioning on the heat sink.

- To maximize natural convection heat dissipation efficiency, the heat sink is designed with vertical fins. For horizontal installations, it is advisable to consider an increase of approximately 20% in thermal resistance.

- The surface of the heat sink is not subject to additional treatments.

Regarding black anodized heat sinks in natural convection, the thermal resistance is reduced by approximately 10%.

As the length of the heat sink increases, the thermal resistance decreases following a nonlinear law. The indicated values refer to the specified lengths; for different lengths, consult the “Length Correction Factor” graph to calculate the multiplication factor to be applied to the thermal resistance, both in natural and forced convection.